Conductor (solid wire or wire)

The application of a cable determines the choice of the conductor. There are three different conductor categories: Solid wire, stranded wire and tinsel cord.

First choice in the production of specialized cables are wires in form of either wire bundles or concentric wires (e.g. Unilay wires, stainless-steel wires).

At SENSOCAB, wire cross-sections range from 0.0019 mm² (AWG 44)

up to 1.3 mm² (AWG 18), depending on the

wire construction. A special type of conductor is the

drain wire.

The rapid development in the production of special cables demands for highly

effective and reliable conductive material. SENSOCAB uses the following

wire material:

- Copper - Due to its very high electric conductivity and excellent formability in warm and cold condition, electrolyte copper is the first choice in today's cable technology. Depending on workmanship and application, copper is available with different surfaces (blank, tin and silver plated).

- Alloy - Applications demanding for extreme torsion-rotation and low bending radii require the use of copper "alloy", since it has exceptional tension strenght and sturdiness.

- StaKu - Staku-wires are steel-copper composite wires. The steel core is copper-plated by electrolytic technology to provide the wires with high mechanical stress resistance.

- Semiconducting synthetics or carbon fibres

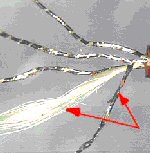

- Tinsel - Tinsel cord provides the best torsion-rotation-stability. Tinsel cord consists of flat-rolled wires (= Laminetten) wrapped around textile yarn (supporting thread). Kevlar, Nylon etc. serves as supporting thread. The flat-rolled wires, either blank, silver or tin plated copper wire have a 01 - 0.03 mm thickness and 0.20 mm width.

|

|

|

|

|

|

Copper wire (24 single wires) without filling element and supporting thread |

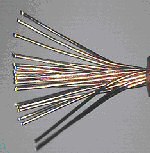

4 ld. Tinsel cord with one supporting Kevlar thread. (the flat-rolled copper wires, wrapped around the supporting yarn are clearly visible) |

|||